Topology Optimization for Multi-axis Additive Manufacturing

Research Background

Conventional additive manufacturing is strictly limited by the self-supporting capability of materials (for further details, see related studies). To address this issue, two strategies are commonly adopted: (1) directly designing self-supporting structures, which significantly compromises structural performance, or (2) adding support structures, which are often difficult to remove. The emergence of multi-axis additive manufacturing technology offers a promising solution to overcome this limitation.

However, not all structures can be successfully fabricated using multi-axis additive manufacturing. The process involves complex multi-axis geometric motions, leading to potential collision risks. Even with the ability to rotate the build platform, the printed structure itself may still be limited by self-supporting angle constraints during deposition. Therefore, it is essential to design structures specifically tailored to the characteristics of multi-axis additive manufacturing to ensure feasible and successful printing.

Concurrent Design Framework

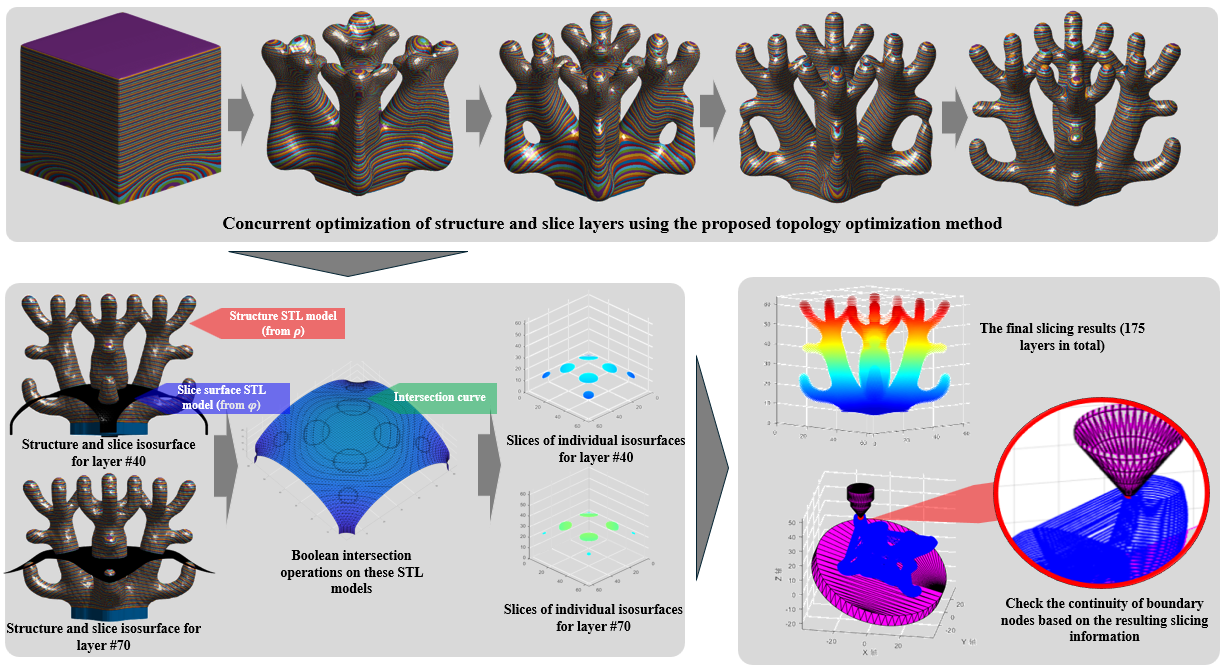

Through a collaborative optimization approach for multi-axis additive manufacturing, both slicing strategies and structural design are optimized simultaneously. This ensures high-quality slicing while maintaining all forming angles within feasible limits and effectively preventing potential collisions during fabrication.

Post-process

Slicing process.

Based on the optimization results, we have developed an in-house post-processing algorithm that automatically converts the optimized design into corresponding G-code, which can then be directly executed by multi-axis additive manufacturing machines.

The validation of printing path (the dynamic performance of the printing path has not been optimized) .

Fabrication Process

Fabrication process.

Related Publication

[1] Xu, S., Liu, J., He, D., Tang, K., & Yaji, K. (2025). Self-support structure topology optimization for multi-axis additive manufacturing incorporated with curved layer slicing. Computer Methods in Applied Mechanics and Engineering, 438, 117841.

Cooperation